An ounce of prevention is worth a pound of cure.

Benjamin Franklin

Linear Tape-Open tapes procured, Zmanda’s proprietary software acquired, your data has never been safer than in the hands of its knight in shining armor. However, the timeless persistence of data significantly relies on the safety of the tape storage. Despite tape storage’s durability and dependability, like any other storage, it is susceptible to external factors such as the environment, storage facility conditions, etc. The key to safety is understanding the parameters that adversely influence it and mitigating the same.

Environmental Impacts on Tape Storage:

Listed below are the optimal environmental conditions for the safe storage of LTO tapes.

1. Temperature: Research and experiments have shown that the tapes must be stored between approximately 60 to 90 degrees Fahrenheit. Recommended operating temperatures are between 50 to 110 degrees Fahrenheit. If changes in temperature are inevitable, ensure to allow the tapes to get accustomed to the new environment for at least 24 hours. If condensation is present, the tape must be allowed to dry naturally. Further, tape storage involves plastic components susceptible to expansion and contraction due to temperature and must thus be accounted for.

A common misconception is that cooler temperatures are ideal for tape storage. However, research shows that storing tapes at very cold temperatures can be just as risky as storing them at extremely high temperatures.

2. Humidity: Humidity is often ignored or given less importance despite its strong influence. Optimal humidity conditions range between 20 to 80 percent. High levels of humidity may result in damage caused by excessive water, while low levels of humidity cause oxide loss and tape decay.

3. Sunlight: Direct exposure to the sun results in harmful UV radiation. This radiation is capable of causing damage to the sensitive data stored in tape.

4. Contaminants: Data stored in tape can be compromised easily by dirt, fingerprint oil, dust, smoke, mold, etc. Thus, clean environments are of priority, and users must be trained to handle exposed tapes without causing any harm to the data.

5. Magnetic Radiation: The primary component of tape storage is a magnetic tape that is susceptible to external magnetic radiation emitted by sources available in day-to-day life. Various industrial machinery, computers, and servers emit these radiations that have an inadvertent effect on the tape, leading to data loss or even erasing the data entirely if powerful enough. Thus, the stray magnetic field of power greater than 50 Oersteds must not be present in the vicinity of the magnetic tape.

| Environmental Factor | Optimal Conditions |

|---|---|

| Temperature | 60⁰ to 90⁰ Fahrenheit |

| Humidity | 20% to 80% |

| Sunlight | Prevent direct exposure to Sun |

| Contaminants | Dirt, oil, smoke, dust, mold, etc., can compromise the stored data. |

| Magnetic Radiation | 0 to minimal magnetic radiation.Maximum Limit: 50 Oersteds |

Environmental factors aside, let us address a few more guidelines essential to preserving data integrity.

Safety of Tapes During Transportation

Tape storage is often stored in offsite locations to abide by the 3-2-1 backup rule. This requires the commute of tape storage between storage facilities and organizations that employ them for storing data. Given below are a few tips to ensure the safe transportation of tapes.

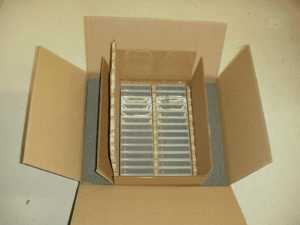

- As indicated above, tapes are susceptible to various environmental conditions and physical distress. To prevent adverse consequences on the tape cartridges, store them in “jewel cases” and seal them in moisture-proof bags. New tape cartridges are protected best by the original packaging left untampered, as the original packaging withstands contaminants, prevents moisture from penetrating, etc.

- If cardboard boxes are used to transport the cartridges, ensure to use multiple layers with padding in between the layers. Confirm that the cartridges fit snuggly to prevent them from rattling and causing untoward damage.

- Ensure that the operation is solely handled by experts who are knowledgeable about the environmental conditions, physical handling, dos, and don’ts, etc.

- Tracking the cartridges and updating the inventory is key to maintaining an updated and comprehensive log. It helps identify lost cartridges by retracing the previous locations recorded in the logs. Moreover, logging the users involved in the process of tape transportation prevents illegal access and aids in conducting further analysis in the event of a missing tape cartridge.

- Enhance data security by encrypting the data on tape before it leaves a facility.

- When transportation is complete, perform a thorough inspection for split cartridges, loose leader pins, etc., and promptly take preventive measures. For instance, in the event of a broken cartridge, immediately copy the data onto a new cartridge for improved chances of recovery.

Importance of a Good Organization System

For every minute spent in organizing, an hour is earned.

Benjamin Franklin

An organized system enforces a procedure to follow, rules to comply with, and a systematic way of achieving goals and targets. The benefits of such a system are limitless; greater efficiency, increased productivity, and greater throughput, to name a few.

Here are a few tips whose implementation results in organized systems for tape storage management.

- Barcode Labels

Right from identifying primary keys in databases to calling each other by our names, unique identifiers have played a key role in identification. As tape storage libraries are of large scale, barcode labels facilitate easy identification and provide the ability to store metadata made available by scanning them. Companies that use tape storage with different compliance guidelines employ these labels to ensure they meet regulations.

- Inventory Management System

Maintaining an up-to-date inventory management system prevents untoward hysteria and panic. A well-tabulated and comprehensive system containing all the required information on the whereabouts of a tape cartridge or drive, and its respective contents, aids in its management. An inventory management system also helps pinpoint tapes in line for rotation, recovery testing, or maintenance. It also eases the process of auditing tape storage.

- Tape Rotation

Operating systems employ a multitude of process scheduling algorithms to schedule processes of different priorities. These algorithms aim to work efficiently and fairly while maximizing the utilization of the internal hardware’s processing power. Similarly, tape rotation is essential for maintaining tape storage in the most effective way possible. As the name suggests, tapes are rotated based on a predefined scheme and algorithm which helps ensure that data retention and minimizing the purchase of additional storage media finds the perfect intersection. Further, tape rotation prevents tapes from being overused, which can lead to unprecedented wear and tear, inevitably leading up to data loss and tape degradation.

A few examples of tape rotation schemes are: First in – First out, Round Robin, Grandfather-father-son, Six, Tape Rotation, Tower of Hanoi.

- Regular cleaning

Organizing and scheduling regular cleaning of tape cartridges prevents contaminants from degrading quality and data loss. Prior to drafting a schedule, personnel must be trained to carry out the cleaning, paying heed to minor details essential to maintaining tape storage.

- Recoverability Testing

A well-organized system must comprise a recoverability testing plan. A recoverability test entails testing the tape by reading its data. The recoverability test quickly identifies inabilities in reading data or signs of a loss in data integrity, allowing for proper mitigation by writing the data to other tapes.

- Calculating Backup Frequency

Companies have diverse sets of data, producing data at different rates and thus having varying frequencies of backing up data. An organized system is at its best when the frequency calculated is the optimal frequency that guarantees data security and backup, resulting in the prevention of unnecessary writes to tapes.

Following these simple tips leads to the prolonged and hassle-free use of tape storage. Customizing the organizational system and assigning responsible and well-equipped personnel to best suit the company’s needs are essential to maintaining tape storage.

Essential tips and guidelines revealed, all that’s left is their implementation and securing data by the best means possible. Who better than Zmanda to entrust your data with superior security and integrity? Zmanda, Betsol’s proprietary product, is your one-stop destination for tape storage. With maestros in tape storage equipped with unbounded experience and knowledge, Zmanda offers services for long-term data archival using tape storage. The Zmanda Management Console possesses a user-friendly GUI to simplify data backup and support the seamless integration of multiple media for backing up data, paying heed to the 3-2-1 rule of data backup. Aside from providing expected deliverables, Zmanda offers game-changing features like tape labeling, tape vaulting, data compressions, and data encryption. Further, Zmanda uses industry-standard data formats that are compatible across platforms and media, reducing the hassle of incompatibility and data redundancy resulting from storing data in multiple formats. In addition to providing backup software, Zmanda also offers top-notch services and timely assistance that various reputed companies have attested to and commended highly.

Experience Zmanda’s mighty capabilities with a free trial for fourteen days that offers unrestricted access to all of Zmanda’s backup components and excellent support throughout the day. For any further queries, technical assistance, or demos, Zmanda’s adroit crew is ready to offer their helping hand.