Introduction

As important as it is to choose the right kind of storage endpoint, it is also important to maintain them. Magnetic media such as tapes have been the past, present, and future of backup and disaster recovery. Their long shelf life makes them desirable to use as storage endpoint. Therefore, it is prudent that enterprises know how to store and care for their magnetic and optical media so that at the time of a disaster it is relatively easier to recover all the lost information, especially if they are stored on-premises. Read on to find out more about what makes or breaks magnetic tapes.

What is Magnetic Media Used For?

Magnetic media is used to store and record:

-

Numeric and textual information

-

Sound or audio

-

Motion or videos

-

Still images or pictures

For any enterprise with special long-term storage needs, tapes are always the go-to storage devices. Therefore, magnetic tape storage media require special environments, care, and handling. Periodic transcription from old media to new media would be necessary, time and again.

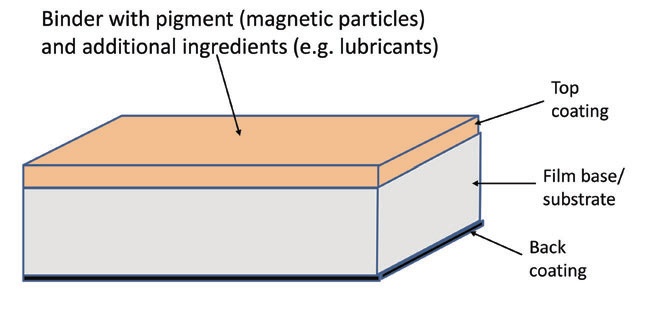

What Constitutes the Magnetic Media?

Knowing what constitutes magnetic media storage enables us to take care of and handle them better.

-

Magnetic tapes consist of magnetic pigments that hold the required information. They are capable of recording and storing magnetic signals.

-

Magnetic media devices are usually combined with a binder that can be a polymer. It has the function of providing a smooth surface to facilitate the transportation of the tape through the recording system.

-

A lubricant is added to the binder to reduce friction.

While the magnetic pigments, binder, and lubricant constitute the top thin layer of the tape, a thicker film backs up the layer that forms the substrate. With just the substrate and the magnetic pigments, a magnetic tape would resemble a sandpaper in texture.

What Can Go Wrong with the Magnetic Media?

There are several factors that can affect the magnetic receptive media. So, knowing about what can go wrong with magnetic media can help us take appropriate measures to increase their life expectancy. Let’s dive in.

Binder Degradation

The binder or the polymer can lose its integrity through softening, embrittlement, loss of cohesiveness, or lubrication. These conditions may be caused due to hydrolysis. Hydrolysis of tapes can be compared to the analogous process observed for open bags of crackers, chips, and cereal. When tapes are exposed to the air, the moisture in the air can break down the complex molecules of the polymer into simpler molecules that could lead to either softening or embrittlement.

The binder polymer will absorb water from the air which can lead to Binder Hydrolysis that can, in turn, lead to the sticky tape phenomenon that causes higher friction and gummy tape surface residues which can produce head clogs, seize and stop in the tape transport, or cause squealing of audio tapes.

Tape baking is a treatment that can improve binder integrity. Treating tapes at 122 degrees Fahrenheit can absorb the moisture from tapes that can temporarily facilitate them to run smoothly so that information can be transcribed to newer media.

Lubricant Loss

Lubrication of tapes can be compared to water absorbed in a wet sponge. Lubricants are used so that low friction can in turn prevent overheating of tapes. They are squeezed in between the tape and the head of the reader where the excess lubricant is squeezed out or absorbed back.

Lubricants are partially consumed every time the tape is played that decreases their level. Some of it either gets migrated to the pin or gets evaporated. Lubricants can also degrade due to hydrolysis and oxidation. Re-lubrication of tapes can be a temporary solution to this problem and information can probably be migrated later on.

However, excess lubrication on the surface of the tape will act as debris and increase head-to-tape space causing signal losses and dropouts.

Magnetic Particle Instabilities

One problem that is most commonly encountered is if there are any changes in the magnetic properties of the particles, the recorded signals can irretrievably get lost. The term ‘Magnetic Remanence’ refers to the magnetic pigment’s ability to retain a magnetic field. The strength of the signal that is recorded is directly proportional to Magnetic Remanence.

Coercivity is another term that defines a magnetic pigment’s ability to resist demagnetization. It refers to the strength of the magnetic field that must be applied externally to change the direction of the existing magnetic field. This can usually happen because of metals around magnetic tapes.

Since Remanence and Coercivity are basic properties of magnets, there is no way of eliminating the problems but storing the tapes at cooler temperatures where there is no influence of other metallic substances should do the trick.

Substrate Deformation

The substrate is usually a polyester that is not immune to the effects of temperature or humidity. Stress, aging, and poor wind quality are some of the things that affect the functionality of magnetic tapes. Constant expansion and contraction of the material can cause dimensional changes that increase the stress.

Non-linear deformation may also occur if the tape pack wind quality is poor. There are specific professional methods of controlling the quality of the tape pack wind.

Six Best Tips to Maintain Magnetic Media Storage

Some of the best practices that can be followed for taking care of magnetic media’s health to avoid the loss of backed up data are:

-

Store the tapes in consistently cool and dry environments.

-

Although tapes have a longer shelf life, data needs to be migrated from old media to new media when required.

-

Tape baking and re-lubrication can be followed now and again to maintain the health of tapes.

-

Tapes need to be protected from external magnetic fields.

-

Consider factors such as Remanence, Coercivity, and Tape Capacity before deciding on the type of magnetic tape to be used to store data.

-

Use professional methods to control the quality of tape pack wind.

Wrapping Up

Needless to say, the overall longevity of the magnetic tape storage can be extended to more than 30 years, if maintained well and certain conditions met. With the dramatic explosion of data every year, it's extremely crucial to preserve and maintain magnetic tapes to prevent chemical instabilities and deterioration. But why worry when it's easy to maintain magnetic media devices by just following simple hacks that are at one’s fingertips? This way, although inevitable deterioration cannot be avoided, we can still slow it down.

Source Credit:

Magnetic Tape Storage and Handling

A Guide for Libraries and Archives by Dr. John W. C.

Van Bogart - https://files.eric.ed.gov/